Balancing your rollers is an important step for roll performance and machine life. Passaic Rubber

Company recommends Roll Balancing on new roller fabrication as well as those in for routine service.

- All Products

- Extrusion equipment – Capstan Puller Belts

- Kaps-All Capping Replacement Belts

- Sandiacre VFFS Replacement Belts

- Rubber Coated Tire Cord Fabric

- Neoprene Flashing

- Rubber Covered Timing Belts

- PACMAC PACKAGING BELTS

- MATRIX PACKAGING BELTS

- POLYBAND WEB SPREADER

- Neoprene Cable Jacketing Tape (1831)

- Feeder Belts

- Vertical Form Fill and Seal Belts

- Capping Belts

- Tube Winder Belts

- Nip Impression Paper

- Metal Bonding

- Mandrel Made Belting

- Custom Calendered Rubber

- Black Seam Tape

- White Seam Tape

- Cured Sheet Rubber

- Uncured Sheet Rubber

- Electrical

- Rubber Tank Lining & Molding

- Truly Endless Belting

- Converting

- Mining

- Construction

- Calendered Fabrics

- Calendered Rubber

- Custom Calendered Rubber

- FDA Approved Rubber Sheeting

- Neoprene (CR)

- Butyl (IIR)

- Chlorinated Polyethylene (CPE)

- EPDM Rubber

- Hypalon (CSPE, CSM)

- Fluoroelastomer (FKM) Rubber “Viton®”

- Nitrile (NBR)

- Natural (NR)

- Styrene Butadiene Rubber

- Silicone (Si)

- Silicone (Si)

- Natural (NR)

- Nitrile (NBR)

- Fluoroelastomer (FKM) “Viton®”

- Styrene Butadiene Rubber (SBR)

- Hypalon (CSPE, CSM)

- EPDM

- Chlorinated Polyethylene (CPE)

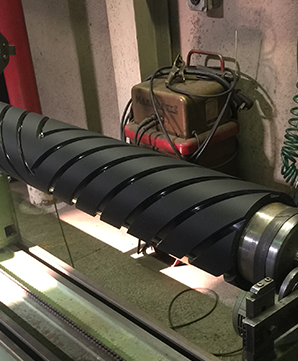

Balancing

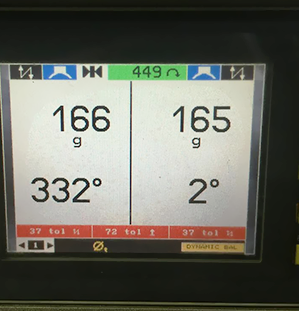

THERE ARE 2 TYPES OF BALANCING

STATIC AND DYNAMIC

Static balancing prevents loping. Loping in the roll profile means there is a heavy spot in a certain area of the roll that causes gravity to pull it down, essentially turning the roll over when the machine is not running. Statically balancing the roll will prevent the roll from loping down. Static balancing is recommended for rolls that do not spin at a high rpm.

Dynamic balancing prevents rollers from vibrating when the machine is running. Vibration causes wavering in plastic film, paper and steel materials. This can possibly lead to an increase in preventative maintenance, uneven coating, laminates and/or processed materials. Dynamic Balancing is recommended for rollers that spin at a high rpm. It is beneficial to dynamically balance a roll to extend bearing life and prevent excess vibration in the machine.