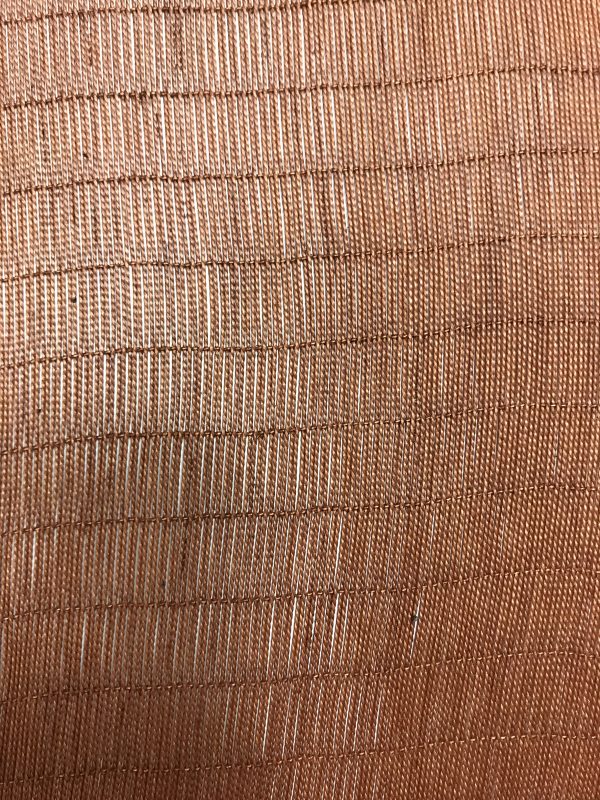

All of our fabrics are treated with RFL – SBR treatment for optimal adhesion during the curing process.

Polyester

- 1000/2

- 1300/2

- 1500/2

- 1000/1/3

Kevlar

- 1500/2

Nylon 6,6

- 840/2

- 1260/2

- 1890/3

We stock various rubber types, hardnesses, and colors based on customer requirements. If these compounds do not meet your specifications, Passaic Rubber can formulate any compound to fit your specific application.

- Neoprene

- SBR

- Nitrile (HNBR, NBR)

- Natural Rubber

- Silicone

- Hypalon

- Millable Urethane

- EPDM

- FDA and USDA approved materials

- Proprietary Formulations

- Flouroelastomers

- 80″Maximum Width Sheeting

- Gauge Range: 0.010” to 1” thick

- Slitting Range: 0.75” to 80” Wide

- 4 Calendering Lines

- Specification Tolerances

- Quick Turnaround Capacity

- Private labeling Available upon request

- Special Trial Runs (50 Yard Minimum)