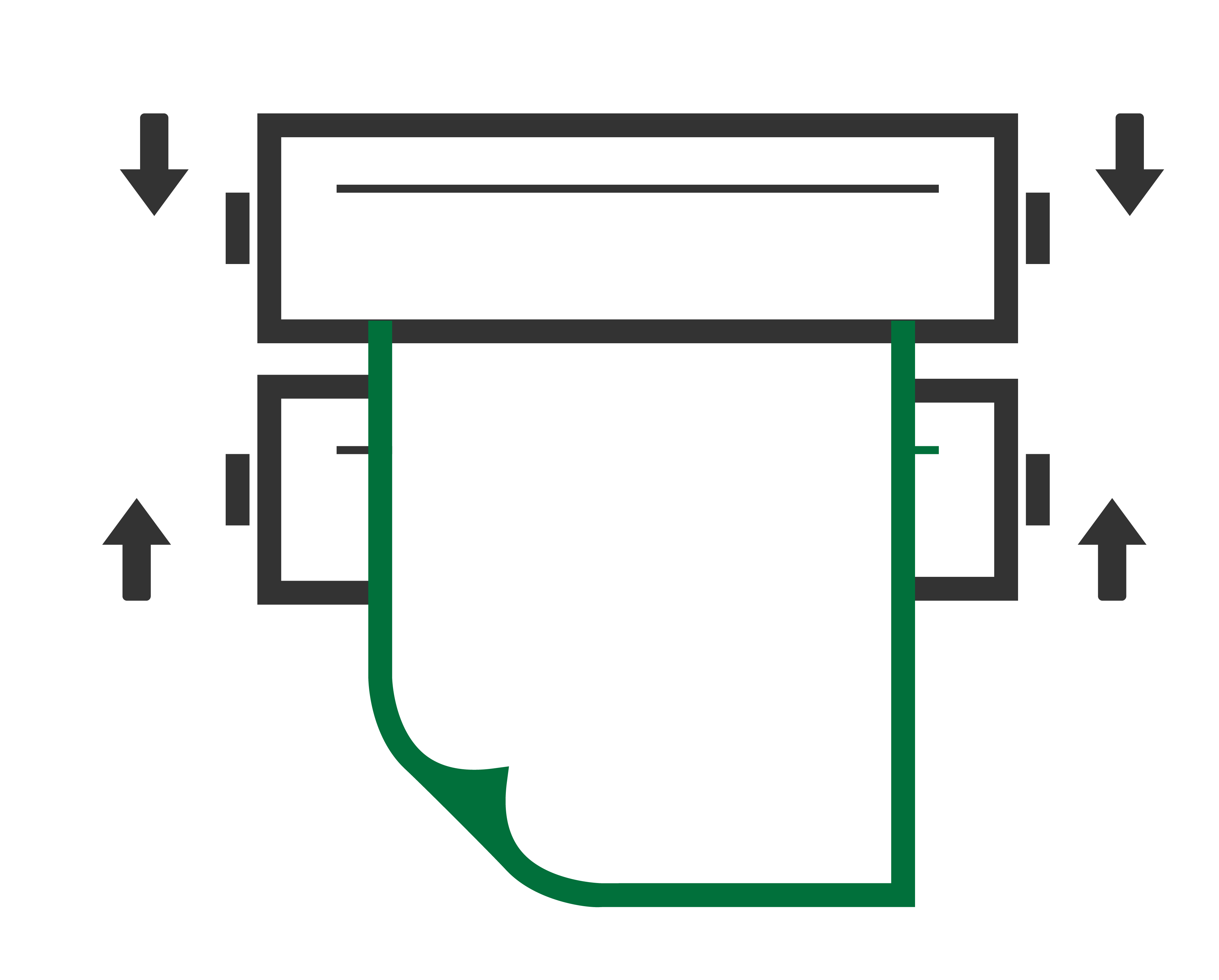

Insert Paper Between Rolls:

Disengage the nip to allow our paper to be inserted. Not much room is needed: 1/8” is sufficient.

After the nip impression paper is nicely centered between the disengaged nip rolls, engage the nip at your standard pressure to make an impression.

Then release & remove the nip impression paper.

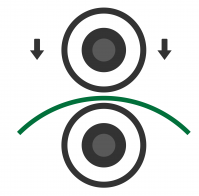

Sideview

Lay nip impression paper on the lower roller, centered, then engage the nip system.

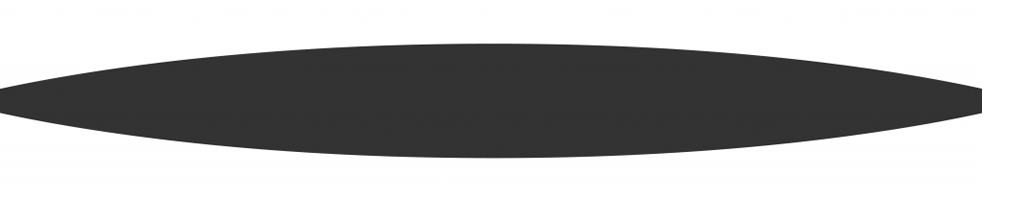

Perfect Nip Result

- Proper Crown

- Good Impression Result

Crown Too Large

- This Roller Crown Is Too Large

Unbalanced Load

- This Shows A Unbalanced Load or Misaligned Rollers

Banding/Wear/Grinding

- Banding, Roll Wear, or Grinding

Check Load & Crown

- Check Load or Roll Crown

(roll diameter issues)