Cotton

Polyester Blends

Nylon

Polyester

Fiberglass

Rayon

Kevlar

Polyester Monofilament

Blended Fabrics

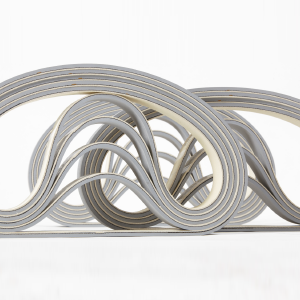

Flat Belt

H Pitch

Neoprene

Natural Rubber (Linatex Equiv.)

SBR

Silicone

E.P.D.M

Nitrile

Hypalon

FDA & USDA Approved Materials

Excellent Grip

Single Piece Construction

No Seams/Splices to Fail

Mandrel Made with Seamless Covers

High Strength Reinforcement (No Stretch)

Available in 40, 50, 60 Shore A

Non-Marking